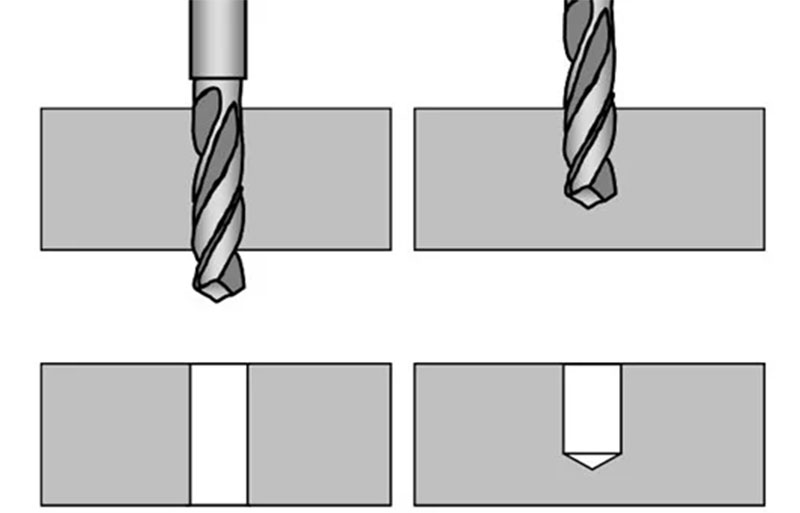

Besides their names, the differences between a blind hole vs. a through hole involve the process and the results. Blind holes do not break through the workpiece; they are only drilled to a specific depth that is a fraction of the total part’s thickness. A through hole or thru-hole is created to go through to the workpiece’s other side.

Machinists create blind holes in the workpiece to make recesses for fasteners. These blind holes often offer aesthetic benefits suitable for automotive, architecture, and consumer goods applications. Through holes are commonly used in assemblies where the components require secure fastening and alignment. However, a blind hole is a perfect choice in situations where you must avoid compromising the workpiece’s functionality or appearance on the opposite side.

In addition, the through holes are compatible with fasteners like bolts, screws, or pins that can completely pass through the material and secured with washers or nuts on the opposite side.